Metal Working

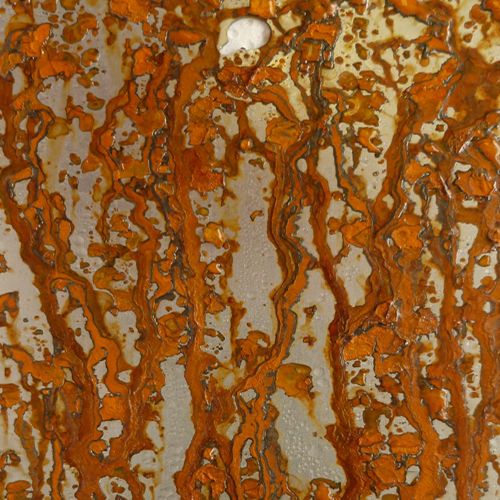

Corrosion inhibitors and rust preventatives.

TINSCO additives for metal working fluids are designed for exceptional effectiveness across a wide variety of applications, including thin film rust preventative fluids, dewatering fluids, cutting and grinding oils, coolants, metal cleaning baths, slushing oils, forming oils, and many others.

They combine maximum product effectiveness with additional handling & storage, health & safety and product classification benefits. With minimal formula disruption, they are easily added, and do not require specialist storage or blending requirements.

Benefits

- Range of ready to use liquids – soluble in a wide range of solvents, oils and synthetic fluids.

- Mobile liquids at ambient temperatures – no heated storage required.

- Easily incorporated during manufacturing stages and can be post-added.

- Excellent corrosion protection properties.

- Excellent water seperating / displacing properties.

- VOC FREE* and free from heavy metals.

- Suitable for ferrous and non-ferrous substrates.

Corrosion Resistance

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

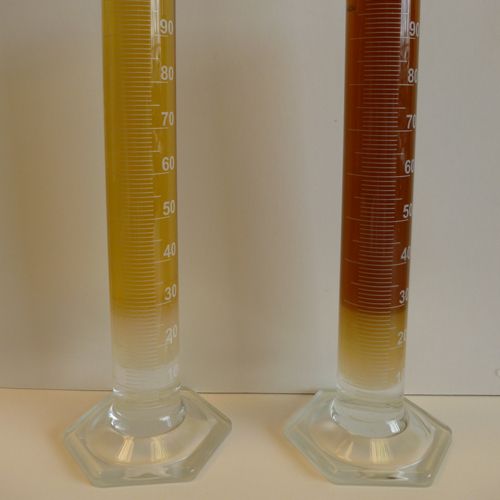

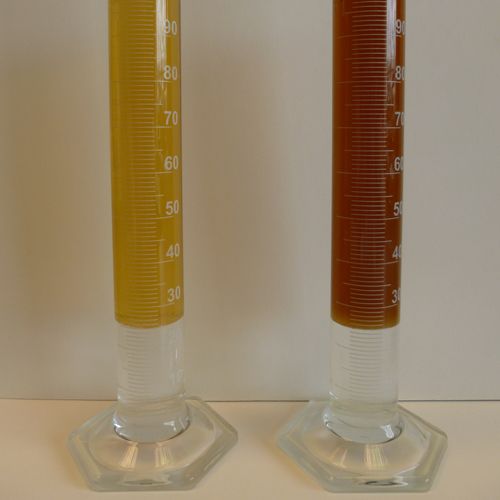

Water Displacement Properties

Method: 75ml of RP solution: 25 ml water; invert 6 times in 100ml graduated cylinder; record time to separate 25ml of water

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

TINSCO

MM-CI 1965

Leading

Competitor

Product Optimisation & Bespoke Development

MGS Chemistry Group is ISO 9001 certified and our laboratory operates comprehensive corrosion testing facilities. We will be pleased to assist in testing, conduct bespoke product development and advise regarding formula optimisation.

To learn more about how TINSCO additives can benefit your business, please contact us.

Products

TINSCO MM-CI 1800

TINSCO MM-CI 1810

TINSCO MM-CI 1900

TINSCO MM-CI 1965

TINSCO MM-CI 1990

TINSCO PCI 407